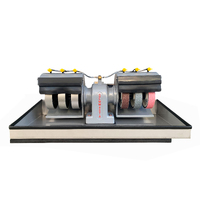

ProCabber 200mm x 6 Wheel Stainless Steel Cabbing Machine

Two Diamond Grinding, Four Genuine Nova Soft Wheels

Notify me when back in stock

PROCABBER (200mm) 8" x 6 WHEEL STAINLESS STEEL CABBING MACHINE

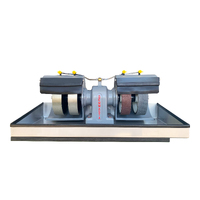

Our ProCabber cabbing machines are Australian made in Ballina NSW. They are fully stainless steel in construction, including the shaft and bearings! Both the motor and the shaft pulleys have keyways to prevent the pulleys from slipping. ProCabbers have a longer shaft than less expensive imported machines, enabling greater spacing between the wheels. This allows much better access to the edge of the cabbing wheels.

Shafts are 1" stainless steel and threaded at both ends. The shaft accepts left and right hand alloy face plates with a 1" UNF thread. The shafts can be used with silicon carbide, diamond wheels or rubber expandable drums of any brand.

The machine comes by default with the following list of components:

Fully equipped with six 8-inch wheels, end plate accessories and polish compound. (options available).

Stainless steel body Machine, with shaft, shaft nuts and machined nylon wheel spacers.

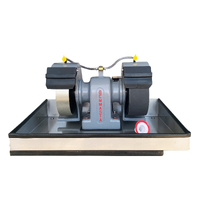

A 1/2hp fully sealed Australian supplied motor that is C-Tick approved. A drive belt and one speed pulley system.

A 8-inch left hand alloy face plate mounted with a magnet so any additional grinding disc can be easily interchanged.

A 8-inch right hand alloy face plate mounted with a steel face so any magnetic backed polishing disc can be interchanged.

Newly upgraded fully brass needle valve water taps with tubing that leads to an aluminium manifold.

The manifold is supplied with a standard male hose fitting.

Left hand bendable water hose for grinding flats. Drain fitting and plug.

THIS CABBING MACHINE NOW COMES WITH YOUR CHOICE OF SOFT WHEELS: There are two main choices, the wheel configuration and the wheel brand. One of the most well known in the industry are (Genuine USA Made Nova Wheels). We are now however offering our own Australian Made Flexmasta Wheels!

General Purpose Set Up

This configuration suite a wide range of gemstones. By default if you are cutting a broad array of stones and many that may be harder like agate and jaspers we suggest to choose a general purpose set up.This consists of two (hard) diamond plated grinding wheels 100# & 220#.Along with four soft (flexible) wheels, your choice of Nova or Flexmasta. The standard grits for these are 280#,600#, 1200#, 3000#. Included is a 320# diamond grinding disc that magnetically attaches to the left hand end plate. A magnetic backed felt polishing pad that attaches to the right hand face plate and a syringe of 50,000# diamond paste.

Opal Set Up

Using finer grades of grinding and sanding is generally a preference for those shaping Lightning Ridge or Coober Pedy opal. Taking a finer approach limits the deep scratches that can mark the softer stones and also helps with the issue of removing too much material. This wheel set up consists of three finer (hard) Diamond plated grinding wheels 180#, 320#, 600#. Along with three soft (flexible) wheels, your choice of Nova or Flexmasta. The standard grits for these are 600#, 1200# and 3000#. Included is a 600# diamond grinding disc that magnetically attaches to the left hand end plate. A magnetic backed felt polishing pad that attaches to the right hand face plate and a 100gram bag of optical grade cerium oxide polish compound.

If you are seeking a customised wheel configuration or wanting to run sintered wheels we can create for you a tailored quote. Our team is happy to give you advice on the best configuration to meet your particular requirements. You will need to organise your own gravity fed container and hose that will attach to the back of the manifold. It is expected that you would have your own basic tools like spanners to tighten your shaft locking nut.

The ProCabber is a single speed machine, however it can be converted to 3 speed with the addition of our optional 3 Step Pulley System for an additional $140.00.

The single speed version runs at 1775 rpm. The optional 3 speed pulleys give you the following range of speeds: 850, 1420 and 1988 rpm.

All customisation and any warranty work is carried out in our own workshop. We have many years of experience in selling and servicing cabbing machines. Unlike our competition, the staff at Gemcuts include professional commercial cutters and can offer the best advice there is. If you are shopping purely on price then be careful - you are only going to get what you pay for!

THESE MACHINES ARE MADE IN SMALL BATCHES. IF SHOWING OUT OF STOCK PLEASE CALL US TO BE PLACED ON A WAIT LIST. THERE IS GENERALLY A 2-4 WEEKS WAIT. THOSE WITH THEIR NAME DOWN GET PRIORITY. 02 66811686

(GPC8)

| SKU | GPC8 |

| Brand | Gemmasta |

| Shipping Weight | 65.0000kg |

| Shipping Width | 0.780m |

| Shipping Height | 0.530m |

| Shipping Length | 1.040m |

| Shipping Cubic | 0.429936000m3 |

| Unit Of Measure | ea |

| Assembled Length | 0.950m |

| Assembled Height | 0.330m |

| Assembled Width | 0.750m |

Gemcuts Pro Cabber

By: Allan Thomas on 27 January 2024As a member of the Laurieton Menshed, Our new Lapidary Group purchased the 200mm Machine with Variable Speed control to teach others interested in the Art of Gem Cutting, As we have Three experienced Gem Cutters that have been cutting for some number of years. The Machine has been preforming beautifully and is a pleasure to operate and highly recommend it to others wanting a quality piece of machinery

(5)