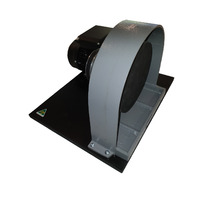

GSP8 Complete Vertical Cabbing Machine

This Australian Made unit is constructed of aluminium alloy casting, stainless steel shaft and heavy duty bearings. Gemmasta machines are finely engineered and manufactured in Ballina, NSW. Each Machine comes with the following accessories that will allow you to finish cabochons;

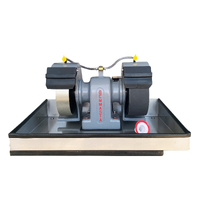

An 8-Inch Machined Aluminium Face Plate with steel disc adhered making it magnetisable. It is attached to the shaft via a 5/8" UNF Left Hand thread.

Two 8-Inch diamond disk with magnetic backing for grinding.

Four resin bonded diamond disks for the sanding process/pre polish.

The disks have a foam core which allows enough "dip" to get an evenly rounded surface on your cabochons.

They are magnetically backed and attach to the face plate without the need for glue. The disks are manufactured by Gemmasta in Ballina and replacements are readily available.

One felt disk on magnetic backing for final polish.

One suitable polish compound.

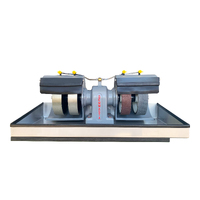

Complete Cabbing Machine General Purpose version

Suitable for a wide range of Gemstones.

-200mm (8 Inch) 100 Grit diamond disk with magnetic backing.

-200mm (8 Inch) 220 Grit diamond disk with magnetic backing.

-Resin Bonded Magnetic Diamond Disks;

#280 (BLACK) #600 (BROWN) #1200 (GREY) #3000 (PINK)

-Felt disk on a magnetic backing.

-SLS #50,000 Diamond Polish Syringe.

-GemLube silicon extender fluid 50ml that helps the diamond spread further and reduces heat.

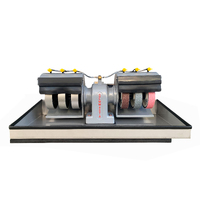

Complete Cabbing Machine Opal Version

Suitable for Fine Opal like Lightning Ridge Or Coober Pedy.

Using finer grades of grinding and sanding is generally a preference for those shaping Lightning Ridge or Coober Pedy opal. Taking a finer approach limits the deep scratches that can mark the softer stones and the issue of removing too much material.

-200mm (8 Inch) 220 Grit diamond disk with magnetic backing.

-200mm (8 Inch) 320 Grit diamond disk with magnetic backing.

-Resin Bonded Magnetic Diamond Disks;

#320 (GREEN) #600 (BROWN) #1200 (GREY) #3000 (PINK)

-Felt disk on a magnetic backing.

-100 grams of Cerium Oxide.

The cerium powder can be mixed into a slurry with water and painted onto the felt disc with a brush.

A water spray bottle is most popularly used for keeping the pad moist.

Using finer grades of grinding and sanding is generally a preference for those shaping Lightning Ridge or Coober Pedy Opal. Taking a finer approach limits the deep scratches that can mark the softer stones and the issue of removing too much material.

Additional Features and Information

This unit comes with a Gemmasta manufactured water kit with an articulated water hose to apply water to the disks. The end nib of the hose twists to adjust water flow and the water manifold inlet accepts a standard garden hose style of connection. We highly recommend using a gravity feed water feed to avoid building up too much pressure in the water system.

The water outlet is through the brass drain outlet at the base of the tray. Simply connect 25mm clear plastic tubing for your wastewater (not supplied).

12mm square profile rubber strip to deflect the water spray back into the tray.

Marine carpet in the tray to prevent damage to stones if they come off the dop or out of your fingers. Supplied on an epoxy sealed board with a 1/3 hp motor (RPM - 800).

Base board dimensions are: 45cm Wide, 50cm Deep & 35cm High. Designed to sit approximately 5cm overhang over the front of bench for drainage hole. Necessary bench depth needed 45cm.

Weight 16.3kg.

New to the Lapidary Trade? Note: The disks are designed to be used incrementally from coarse to fine. Skipping steps can result in a dull or scratched finish. Water must be used on the discs when grinding or sanding. A water spray bottle is recommended to keep the cerium moist and an extender fluid to help spread the 50,000-diamond compound.

Polish compounds should always be used on a separate felt with no risk of cross contamination. Storing them in a clean plastic bag when not in use is advisable to not gather any dirt.

Care Of Steel Diamond Plated Products

At the end of each working day stack any laps vertically to dry (a dish draining rack is good for this). Care should be taken to dry any steel diamond plated disks and steel backing plates. A light spray of Inox or WD40 between uses will help prevent surface rust forming. Do not use chemicals such as rust converters on the plated disks as the chemicals may destroy the plating and cause even greater rusting.

Safety First: Safety glasses should be worn when grinding with any abrasives!

Stone dusts as well as organic material dusts can be very hazardous. Protective breathing equipment such as a face mask should be used to protect your lungs. Good ventilation is also highly recommended.

(GSP8_C)

| SKU | GSP8_C |

| Brand | Gemmasta |

| Shipping Weight | 26.0000kg |

| Shipping Width | 0.630m |

| Shipping Height | 0.520m |

| Shipping Length | 0.630m |

| Shipping Cubic | 0.206388000m3 |

| Unit Of Measure | ea |

| Assembled Length | 0.500m |

| Assembled Height | 0.340m |

| Assembled Width | 0.450m |

Simple to use, fast for Cabbing, space saving and

By: John Court on 5 December 2025Since we only used wheel cabbing machines whilst learning at the club it was a bit daunting to buy a vertical cabber as our home machine. However after having used it for 3 months I can confirm that most techniques transfer from one type to the other as long as you realise how much faster the vertical cab will cut since it has a larger contact point with the stone. This machine is really quite simple but very well engineered, with quality components and good assembly. It fits into a fairly compact space in our garage and setup is incredibly quick and simple (attach hose, power and bucket and away you go). The fast change of disks from grinding to polishing/sanding due to the magnetic backing is quite elegant and shows the design thought that has gone into this machine. All round very satisfied with this purchase and it is making our hobby much more accessible and enjoyable. Well done gemcuts!!

(5)

Good introductory machine and might be all that yo

By: Neil on 19 December 2020I am a member of the local lapidary club, so use all of the standard grinders and cab sanding machines there. I bought this one for home use, and after giving it a workout on a good number of stones (particularly opal), I love it. It doesn't take much space in my workshop (it sits on top of my table saw table) and is much cheaper than going for a wheeled machine. Swapping magnetic disks is quick and easy, and centering them is OK after some practice. Flat lapping stone backs is simple, and I can now get a good polish that I'm happy with. I could say that I prefer using this machine compared to the higher-end ones. I can't think of a way to improve it, except perhaps the addition of a speed control, but even that is probably unnecessary. Two thumbs up from me.

(5)

In my experience!

By: Philip on 22 July 2020Hi, I’m an opal cutter who is accustomed to a flat vertical machine to cut on, I learned back in 1992 that way when you had to keep dipping stone in water to keep it cool. I adapted my own machinery to get by til now, so this Is a great find for me. The price is fantastic, delivery on time, and put a drainage hose on and away I went. The magnetic system makes this very versatile yet space saving. I was surprisingly (no offence to manufacturer) impressed with the quick grinding capability of the 150grit , watch your knuckles, and gave it a good work out and didn’t notice any issues with the grit wearing, I need this to last me a while. I also like to be able to cut reasonably flat faces when needed which this allows me to do. After hrs of constant use I noticed The need to keep refilling my small reservoir, so opted instead to connect it directly to my outside tap by hose connection, and I know they say not recommended in case to much pressure, but I just open the machines tap fully, THEN, turn the outside tap on So as not to over pressurise the hose, just be careful. Sorry this is the first review I’ve ever done not sure what the protocol is, but that’s my experience. Have fun ✋

(4)